JVC XRCDs: A Blueprinted Compact Disc

Some of my closest friends are car nuts. In fact, my best friend loves to search out the perfect car for restoration and go for it. He’s done it with a ’65 Corvette convertible, a ’67 Porsche 911, Porsche 914 and is currently staring down years of work on a Triumph TR6. After a visit to Detroit this past summer, I couldn’t help but relate to the passion, patience and resources that it takes to do what he does (along with the patience and accommodation of his spouse…his garage has three cars in various stages of assembly in it!). Making recording is similar in so many ways (including the patient partner).

I bring up automobiles this morning because I remember the concept of “blueprinting” an engine. The auto companies produce a detailed specification for their engines using CAD computer applications. The actual milling of the metal and fabrication of the various parts introduces small errors (certainly within acceptable tolerances) that make the parts less than perfect.

However, if an engine is “blueprinted” then each part is brought in line with the exact specification as envisioned by the design engineer. The result is that a “blueprinted” engine is much closer to the ideal engine than those that you and I get in the cars that we purchase from the sales lot.

That’s what JVC does when they re-release a classic album on an XRCD type compact disc. The XR stands for “Extended Resolution”. XRCDs usually cost about twice as much as a standard CD. There is nothing extended about the resolution of an XRCD.

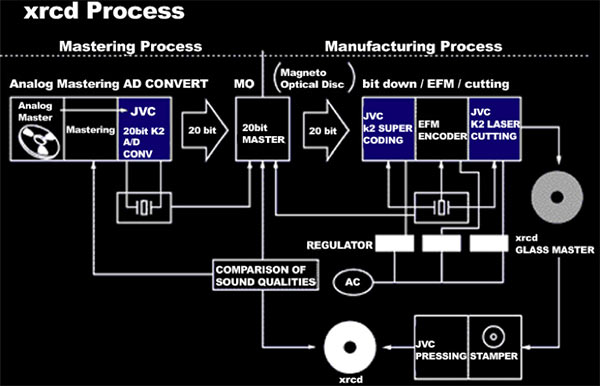

Figure 1 – BLock diagram of the HVC process for creating XRCDs.

Making an XRCD CD is like “blueprinting” an engine. The entire mastering and manufacturing process is more tightly controlled, the pits are positioned with greater precision and advanced dithering the input signal from 20 bits to 16-bits is employed (dithering is the process of randomizing the least significant bits of a series of words to minimize quantization noise). However, the end result is still a Redbook Compact disc, which means it can’t actually have any additional resolution! It might be more perfect CD but to charge double for simply meeting the Redbook specification seems a dubious model. It would be nice if all CD were made to this higher standard.

The JVC magic is in the mastering process. Recordings to be prepared for CD release are either analog or digital (PCM or DSD) when they arrive at the final mastering stage. If the master is digital then the transfer to the mastering system is done via a digital transfer. Hopefully, the master contains more than 16-bits so that the mastering engineer can manipulate the amplitude and EQ without losing any of the low level information. If the source is an analog tape (which it seems the folks at JVC count on when creating an XRCD) the conversion to PCM digital is done at either 20 or 24-bits using a patented “K2” analog to digital converter. I’m sure the “K2” converters are very good or at least were state of the art back when XRCDs were first introduced back in 1995, but converters have improved dramatically in the intervening years. Maybe they should come out with a “K3” process (bigger numbers are always better).

The digital file is then sent on a “magneto-optical disk” to the JVC manufacturing plant. The engineers use a Rubidium clock to minimize jitter and down-convert the 20/24-bits words to 16-bits using a “super-coding” process. Remember that virtually all commercial music releases and absolutely ALL of the ones that were originally recorded on analog tape have less than 16-bits worth of dynamic range. In reality, the “K2” process need only worry about getting 10-bits or 60 dB of SNR into the glass master. All of this craziness about 20 and 24-bit dynamics used on analog masters is overkill.

The replication facility encodes the master using EFM (Eight-Fourteen Modulation), which is a method of ensuring that there will be some “ones” in the digital stream to keep the optical reader happy. The resultant 16-bits is processed through a “proprietary Extended Pit Cut DVD K2 laser technology” to produce the glass master. This process uses a laser beam recorder (LBR) to etch the pits into a piece of glass. This glass master is then used to create stamping masters from which CDs are pressed.

The article I read says that the XRCD process creates “precise pit lengths to eliminate time jitters”. There is no jitter associated with the position or length of the pits on a CD. The data is read by the optical laser from the pits (and lands) and re-clocked within any quality CD player. Basically, it’s a stream of words pulled from the pits and then sent out to the DACs in a tightly clocked sequence. The original rubidium clock is old news by then.

I’ve posted on this topic previously. The resolution of a Redbook CD cannot be “extended” by using better mastering methods or custom processing of any kind. There will always be 44.1 kHz samples and 16-bit words on a CD. The best that can be said about XRCDs is that they are among the best CDs ever replicated. But the quality of the source audio and the quality of the mastering process determine the overall sound of the final replicated CD much more than the “K2” converters or XRCD label. This is another example of marketing over media.

If the music you want is available as a normal CD file or download, you should acquire it that way. If you spend $35 on an XRCD, you’re wasting your money. Here’s a troubling and completely impossible statement from a review on Amazon of the XRCD of Steve Miller’s “The Joker”, “Without a doubt, this is a High Resolution CD”.

“The resolution of a Redbook CD cannot be “extended” by using better mastering methods or custom processing of any kind. There will always be 44.1 kHz samples and 16-bit words on a CD.”

While it is true that whether a digital file is on a regular CD or an XRCD, it is the same, wouldn’t the use of a better (K2, K3, …) ADC result in a better digital file? which is to say, a digital file that more accurately reflects what is on the original analog tape? Moreover, wouldn’t a more perfectly manufactured CD result in a CD that could be read with fewer read errors (jitter)? Surely the differences in ADCs are audible, not to mention jitter. Of course, as has so often been noted in these posts, nothing is going to turn something recorded on analog tape into HD-Audio.

The CD specification known as the Redbook defines everything about compact discs. All producers of discs at every stage should use the best equipment, the best techniques, and the best materials to take optical advantage of the spec. But a CD is a CD is a CD…end of story. The K2, K3 etc processes are marketing spin only. Errors on CDs are corrected as part of the specification and jitter is handled at the DAC. XRCDs sound great…but no better than normal well made CDs.

Pingback: Positive Feedback

If we are to believe that eliminating raw errors is so important, why is there no concern over the error-rate of the internet connections used for downloading software over the internet, where a single erroneous bit can cause a crash?

Robert Harley of the Absolute Sound has demonstrated that the correction-scheme used for CDs absolutely eliminates essentially all reading-errors (down to the parts per billion), assuming that a CD is in reasonably good condition. So, there’s no point in reducing read-errors beyond the level provided by a regular CD. (The improvement caused by using CD-treatments turned out to be due to the reduction in laser-servo-hunting and the resulting reduction in glitches on the analog power supply in CD players where the transport wasn’t sufficiently isolated from the analog section. The corrected error-rate was not improved.) What matters is the quality of the recording stored on the CD, and the quality of the playback unit.

The biggest breakthrough in digital audio in general since the development of oversampling A-to-D converters, as far as I can tell, has been in improvements in the digital interpolation filters in the DACs in the playback unit, and mainly the elimination of pre-ringing, which has been identified as the source of “CD-sound,” i.e. the sheen and the artificiality, not the smeared/scrambled, image-less sound of the 20KHz brick-wall filters used in 1st generation digital recorders.

I never spent much on CD’s or CD players, and I believed for a long time that there was no hope for CD’s as a musical medium and tried to avoid listening to CD’s closely, until I heard a 2006 recording of Beethoven’s 9th played on a modern CD player circa 2015 on KUAT, and accidentally listened closely and realized that it sounded better than I thought a CD could sound. The CD in question has an SACD layer, so I contacted the station and asked whether they had played the SACD layer, to which they replied that they had no SACD players. That’s when I realized that there had been a revolution in CD playback (mainly due to the elimination of pre-ringing in digital interpolation filters), and that CD’s do indeed have musical potential. I’ve since acquired a dirt-cheap Nobsound Bluetooth 4.2 Lossless Player (see my review and comments on Amazon). It uses a Sabre DAC, which epitomizes this revolution, and have concluded that I have to need for high-resolution recordings, which the same lossless player can play, because I am satisfied with the sound quality of CD’s. This dirt-cheap player is the fulfillment of a 30-odd year-old dream to be able to obtain analog-like audio quality from a run-of-the-mill CD played on a cheap playback unit. There might be better units in the same price range, but I don’t have the luxury of listening to a bunch of units, and no professional reviewer would even consider reviewing such a cheap unit. But considering the ingredients, (the Sabre DAC, a TI 5532 pro-grade op-amp-based output stage, a fairly large power transformer with separate windings for the digital and analog sections, and +/-15VDC rails for the output stage), it will be hard to beat the Nobsound’s sound quality by much without spending a lot more.

By the way, the article states that “The data is read by the optical laser from the pits (and lands) and re-clocked within any quality CD player. Basically, it’s a stream of words pulled from the pits and then sent out to the DACs in a tightly clocked sequence. The original rubidium clock is old news by then.” However, the sampling-clock is “built into” the samples, insofar as the precise time at which a sample is taken determines the sample’s precise amplitude. The samples are built into the stream, and extracted from the stream and clocked into the DAC by the playback unit’s clock, which ideally is a single-box player with a super-low-jitter clock at the DAC’s clock-input, and everything else in the player slaved to it. The data would be run through a multi-stage RAM buffer so that the data-rate coming from the CD, which fluctuates due to the nature of mechanical systems, can be smoothed out before reaching the DAC.

If you’re willing to spend extra for an XRCD, SHM, or whatever, you should be able to count on getting a good copy. If the producers of XRCD’s, SHM’s, etc. are just counting on the placebo effect to convince us that the sound of XRCD, SHM, etc. is superior, and don’t bother to use a good digital copy, there’s a risk that the reputation of their product, and their business, could be destroyed when people in general realize that they don’t sound any better than average CDs. So, I assume that high-priced CD’s sound better that the run-of-the-mill versions, but not because of their physical superiority.